Depending on the type of glass produced—float glass, container glass or fiberglass—the production processes and heat-enclosure requirements differ considerably. Detrick offers appropriate constructions for each of these industries, including suspended feeder end walls, waist walls, waist cover arches, front walls, noses, roofs, float bath entrance hoods, and float bath entrance and exit lintels.

Fiberglass and float glass manufacturers appreciate the stability and physical strength of our refractory constructions for their own specific reasons: in fiberglass production, for their high resistance to chemical attack; and in float glass production, for their ease of installation and successful prevention of batch contamination.

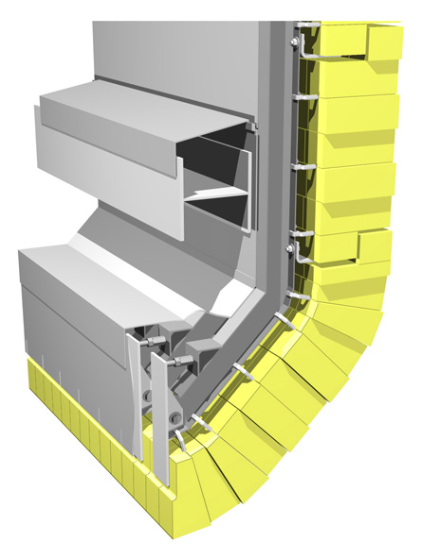

The refractory for the glass industry is specifically designed for the individual customer’s needs. Detrick is capable of supplying silica, bonded Alumina-Zirconia- Silica, fused AZS and bonded mullite alumina refractory. To increase thermal efficiency, insulation can be incorporated on these walls. Suspended feeder end walls with various combinations of these refractory materials have provided excellent service for extended furnace campaigns.